|

| Prophabot (left) and Monty (right) made by Amy and Dan Mather |

These toys were made by two of our favourite young scientists Amy and Dan Mather, who have worked with us at the Museum of Science & Industry for the Maker Faire as well as previous Festivals. Amy's Prophabot won the student category of The 3D Print Cup this year. You can read more about her experience creating this in her blog.

Lab Equipment

|

| 3D printed lab equipment, made in Manchester |

The pinch valve is part of a larger assembly for environmental research on the carbon dioxide emission of soils. The interlocking parametric grid and racks are customised for holding laboratory equipment such as petri dishes and sample bottles, and the design parameters can be altered to make holders for different objects. These objects were designed using open-source tools and the design is freely available via http://drelliott.net. A locally manufactured open-source printer was used to print the objects. With thanks to David Elliott, microbial ecologist in the Division of Biology and Conservation Ecology at Manchester Metropolitan University.

Spider

The video to the left shows the 3D scan of a Huntsman spider, the print of which is also included in the "cloud" of objects.

|

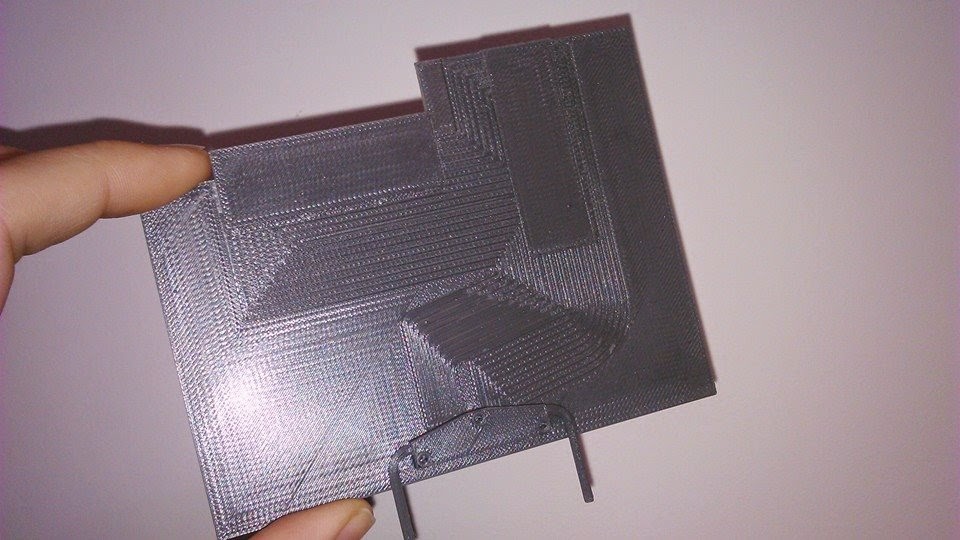

| 3D printed LHCb upgrade detector module |

The LHCb experiment is one of the four large experiments at the Large Hadron Collider at CERN. Its purpose is to investigate the difference between ordinary matter (stuff that we are made from) and antimatter (same mass as the stuff that we are made from, but oppositely charged). The experiment will undergo a major upgrade in 2018. The University of Manchester will construct modules of one of the detectors that is closest to the proton beams (called the VELO: Vertex Locator). They will measure the positions of particles forty million times every second. This 3D printed module has been produced by CERN as part of the design studies for these modules. With thanks to Rob Appleby, accelerator and particle physicist at the University of Manchester.

There are many more fascinating objects included in the exhibition, which opens this Thursday (the install of which has been the backdrop for a couple of our #scienceselfies this week).

3D: Printing the Future opens Thursday at 12pm and will stay at the Museum of Science & Industry until 19th April 2015.

Our #msf14 #scienceselfie with a sneak peek of the install this week, ahead of opening on Thursday.

No comments:

Post a Comment